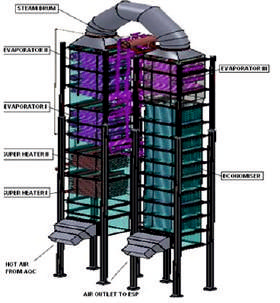

WASTE HEAT RECOVERY BOILERS (WHRB)

Key Features Of SITSON WHRB

- SITSON Waste Heat Recovery Boilers are used to recover waste heat from exhaust gas of spong iron kiln, DG Sets and exhaust gas from gas turbine. The steam generated by WHRB can be used for process heating or generating power in a steam turbine.

Design Features of SITSON WHRB

- Single drum construction for reduced thermal stress during start - up & shutdown; special drum internal that promote circulation & ensure high steam purity.

- Fast Start up and shut down.

- Fully welded construction for quicker start-ups & shutdowns with welds safely located outside the gas path for higher reliability and longer life.

- Membrane wall construction for tight sealing and minimum leakages.

- Suitable to economiser steaming for better off - design operation; fully drain - able super heater for higher reliability

- Effective soot blowing system.

- Boiler-Turbine-Generator (B. T. G) packages available and can be offered on a case-tocase basis.

Operating Range

- Capacities: 8 to 80 TPH.

- Pressure: Up to 110 kg/Cm² (g)

- Temperature: Up to 490 to 510°C

- Waste Gas - sponge Iron Kiln / Exhaust gas of gas turbine / Waste gas from solid waste incinerator / Exhaust gas of cement kiln.